Custom Wheel Module for Future-Proof Mobility

An e-mobility start-up partnered with Vlukon to develop a heavy-duty wheel module. Vlukon proved ideal for the rapid delivery of prototypes and wheels that deliver genuine safety.

Client Overview

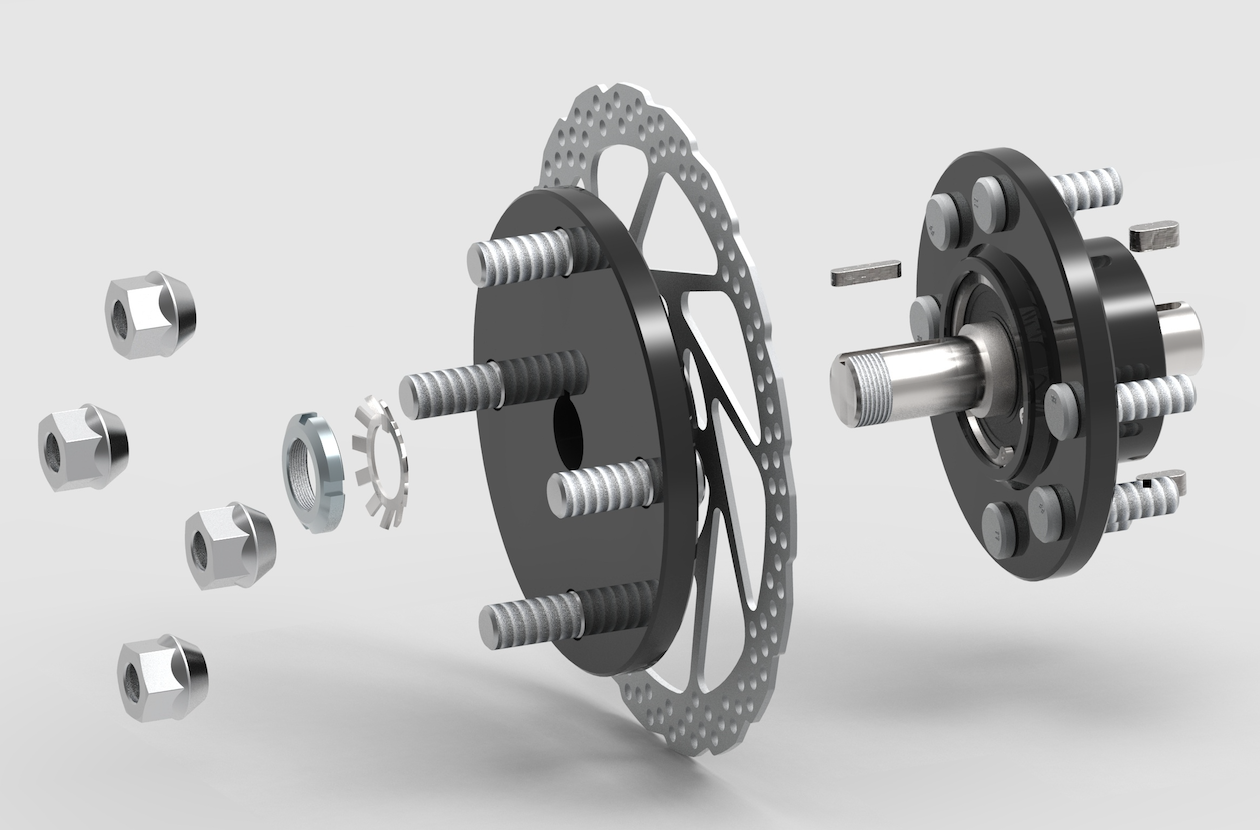

Client: Matglow — a start-up specialising in applied research and experimental development in e-mobility, smart cities, renewable energy and defence. The company discovered that the interface between the wheel, the knuckle and the suspension was critical; off-the-shelf solutions failed to meet the required load and safety criteria. Vlukon designed a bespoke heavy-duty wheel module that is both rugged and optimised for rapid iteration.

The Challenge

Matglow needed a robust, durable connection between the wheel, the knuckle and the suspension system. Standard modules failed under load and posed a safety risk—unacceptable for vehicles destined for real-world deployment.

The Vlukon Solution

- European bespoke design: a heavy-duty wheel module tailored to Matglow’s specific load scenarios.

- Prototype-friendly production: small batches and fast iterations without long lead times.

- Dedicated technical support: ongoing collaboration with Vlukon engineers throughout the development process.

Collaboration & Implementation

The joint engineering process was constructive and well guided. Matglow commented that response times could be improved, which Vlukon is now addressing as part of continuous service enhancement.

Results to Date

- Quality uplift: immediate increase in confidence regarding wheel integrity and overall build quality.

- Positive initial feedback: the prototype performance shows strong promise, with further testing underway to quantify outcomes.

What Lies Ahead?

Matglow plans to deepen the partnership with a view to competitive series-pricing once the prototypes are fully validated. Both parties see clear opportunities for scaling—turning a successful prototype into a reliable platform component.

Client Testimonial

“We would recommend Vlukon due to their excellent engineering team.” — Matglow